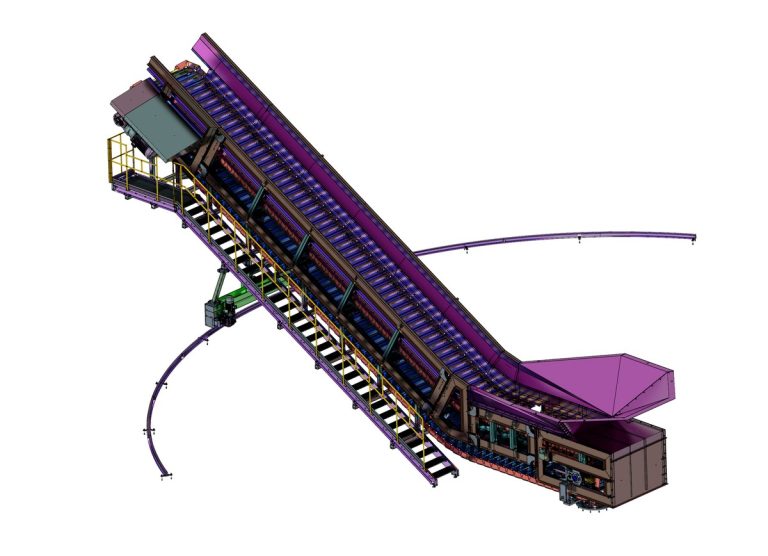

Steel plate conveyors consist of overlapping plates held together by pins. These plates create a seamless surface that can support a wide variety of materials, from bulk parts to individual components. The chain plate conveyor consists of a power unit (motor), a drive shaft, a roller, a tensioning device, a sprocket, a chain, a bearing, a lubricator, a chain plate, etc. Among these, the main two parts of handling materials are the chain, which uses its cyclic reciprocating motion to provide traction; and the metal plate as the carrier in the transportation process. The principle is to use a series of chains fixed to the traction chain to provide traction and to use a metal plate as a carrier to guide the material to be transported in a horizontal or inclined direction.

Automotive Industry: Transportation of car parts and assemblies at different production stages.

Mining and Quarrying: Transporting heavy, abrasive materials such as ore and rock.

Food and Beverage Industry: Transport of packaged products, bottles, and cans on production lines.

Recycling and Waste Management: Transportation of sorted recyclables and waste materials.