If ships operate in areas where SOx emissions are controlled, the air polluting nature of the flue gas can be reduced by using low-sulfur fuel or by cleaning the exhaust gases using SOx scrubbers. Open-loop, closed-loop, and hybrid cleaning systems are used. The basic technology is the same in all these systems. When the exhaust gas enters the system, water is sprayed on it. SOx reacts with water to form sulfuric acid. In the open and closed cycle system, the natural alkalinity of seawater neutralizes the acid. In a closed-loop system, caustic soda helps do this. The hybrid approach allows operation in closed-loop mode when necessary, for example, while in port or during maneuvers using caustic soda.

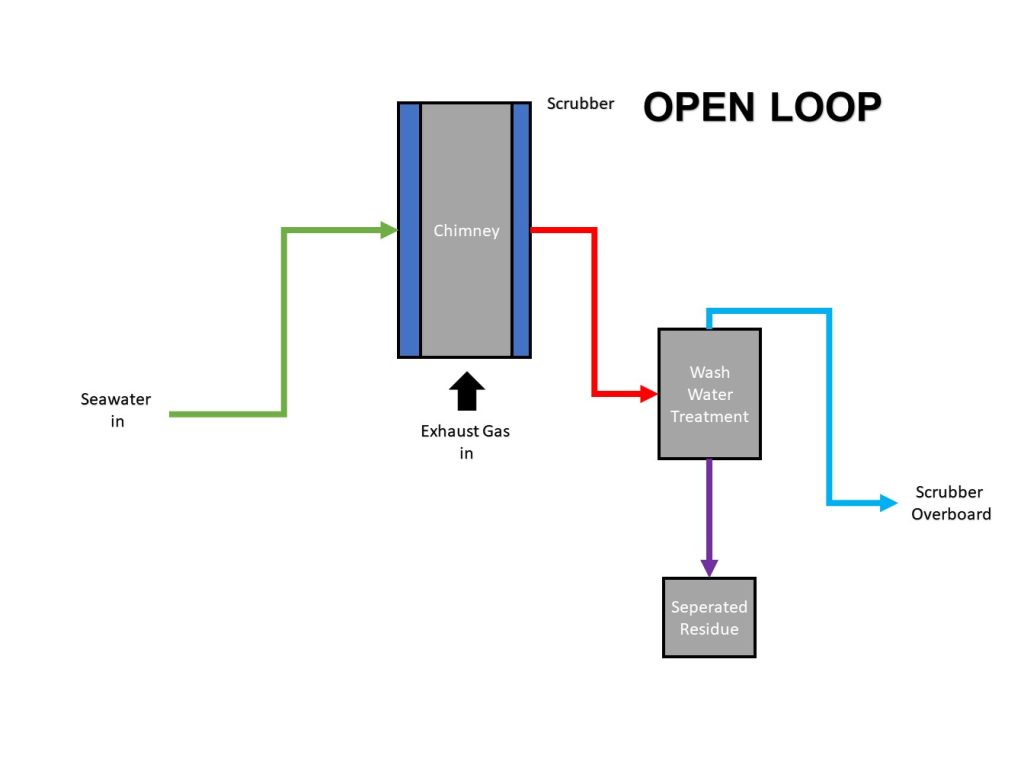

Open Loop System

This system uses seawater as the cleaning and neutralization medium; There is no need for additional chemicals. The exhaust flow from the engine or boiler passes into the scrubber and is purified with alkaline seawater only; The volume of this seawater depends on the size and power output of the engine. This system is extremely effective but requires a large pumping capacity as it uses large amounts of seawater. The open loop system works well where the seawater used for scrubbing has sufficient alkalinity but seawater with a high ambient temperature as well as fresh or brackish water is not effective and cannot be used. For these reasons, the open loop scrubber is not considered a suitable technology for areas where salinity levels are not high, such as the Baltic.

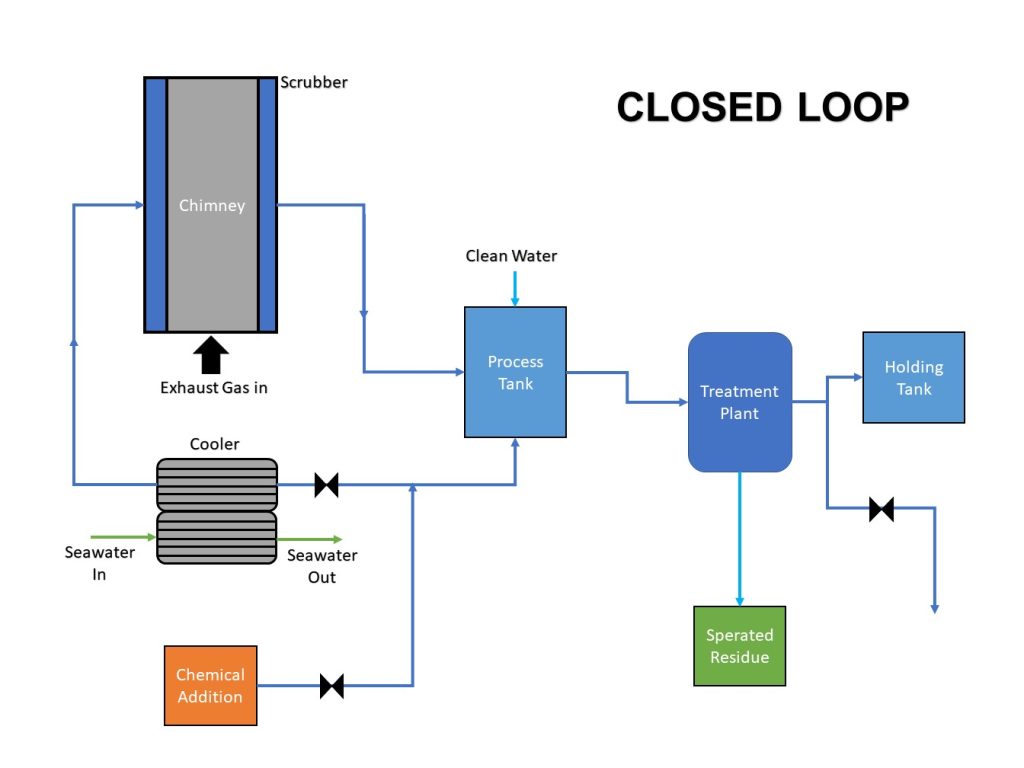

Closed-Loop System

A closed-loop system operates on similar principles to an open-loop system: it uses freshwater treated with a chemical (usually sodium hydroxide) as the cleaning medium rather than seawater. SOx from the exhaust gas stream is converted to harmless sodium sulfate. Before being recirculated for use, wash water from the closed-loop cleaning system is passed through a process tank where it is cleaned. Ships can either carry fresh water in tanks or produce the needed water from on-board fresh water generators. Small amounts of wash water are removed at regular intervals into holding tanks to which fresh water can be added to prevent sodium sulfate from accumulating in the system. The closed-loop system requires almost half the volume of wash water as the open-loop version, but the system requires more tanks. These include a process or buffer tank, a holding tank where discharge to sea is prohibited, and a storage tank that can regulate its temperature between 20° and 50°C for sodium hydroxide, which is usually used as a 50% aqueous solution.

Gallery;