Heat exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or mechanical device to a fluid medium, often air or a liquid coolant.

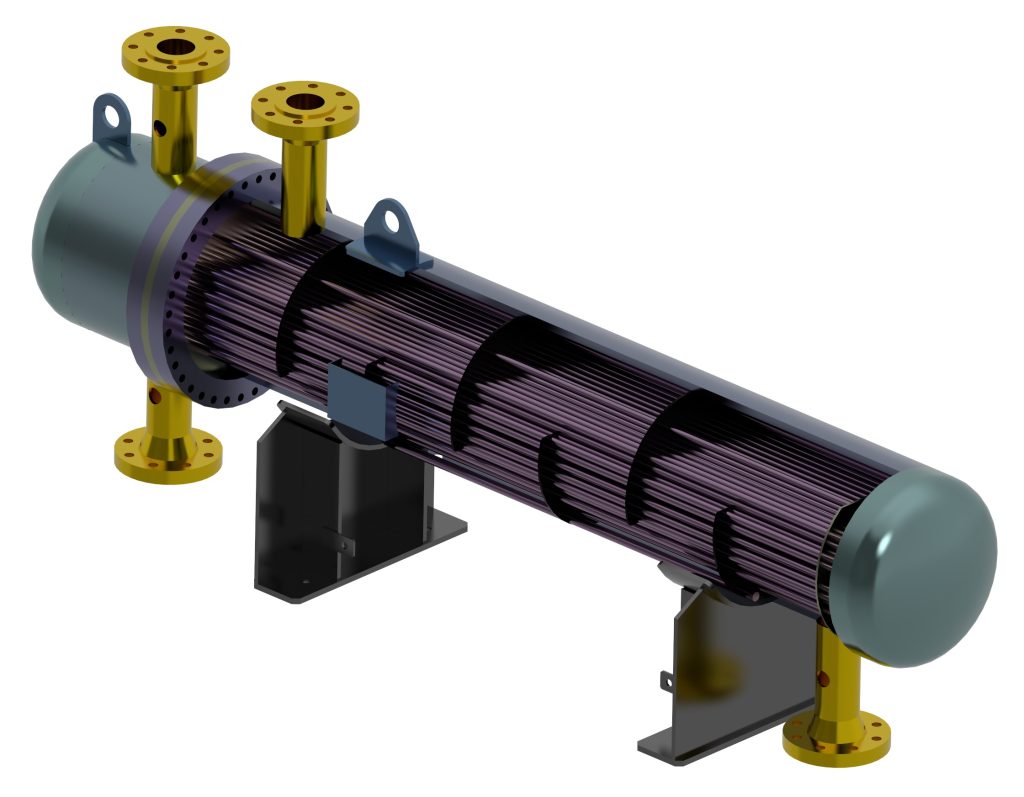

Industrial use of shell and tube heat exchangers is widespread, used in chemical, food, oil and gas and other fields. They are widely used in various industries to transfer heat between two fluids without direct contact. Some of the main industrial applications of shell and tube heat exchangers include.

Heating and cooling processes in chemical plants.

Condensing and evaporating duties in refineries.

Heat recovery systems in power generation facilities.

HVAC systems in commercial and residential buildings.

Refrigeration systems in food processing plants.

Thermal management in oil and gas production facilities.

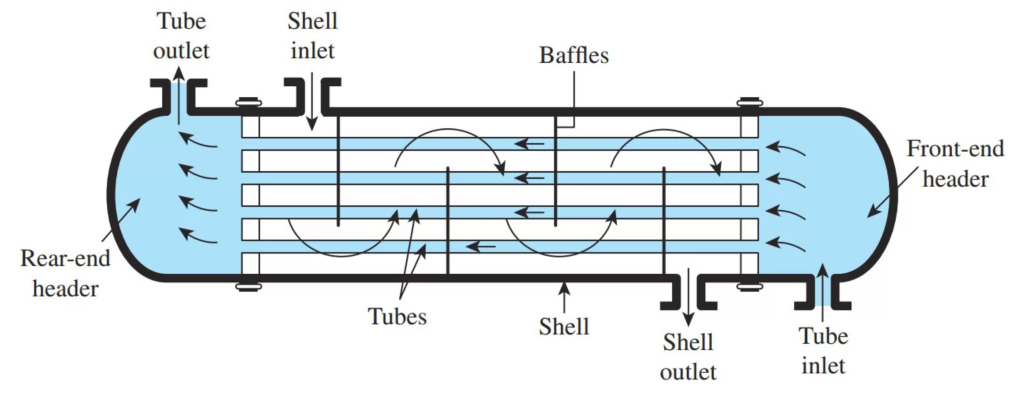

1. Shell

The shell is the outermost part of the heat exchanger that holds the tube bundle. A cylindrical container usually made of steel or other suitable materials

2. Tubes or Tube Bundle

A collection of parallel tubes running the length of the shell form the tube bundle. Depending on the specific use, tubes can consist of different materials such as stainless steel, copper, or titanium. The diameter and thickness of the pipes are also important design parameters.

3. Tube Sheets

Tube sheets are solid sheets that act as a barrier between the tube bundle and the shell. They are usually made using steel and are fused to the shell to provide a sturdy, leak-free closure. Pipes are threaded through holes in tube sheets and flared or welded.

4. Baffles

Baffles are plates or rods inserted into the shell to regulate the movement of liquid around the bundle of tubes. These can be in the longitudinal or transverse direction and are intended to increase the efficiency of heat transfer.

5. Inlet and Outlet Nozzles

Inlet and outlet nozzles serve as the entry and exit points of the fluids in the heat exchanger. These connections are usually placed at opposite ends of the shell and connected to the pipes and shell using flanges or other fittings.

6. Expansion Joints

Expansion joints are flexible connectors that accommodate the thermal expansion and contraction of the pipe bundle. These connections, usually located at the inlet and outlet of the heat exchanger, are made using metal bellows or other flexible materials.

7. Support Structures

Support structures provide a solid foundation, holding the heat exchangers in place. Support structures can be temporary or permanent and are made of steel or other materials.