Prefabricated hydraulic piping

Hydraulic pipe systems are generally manufactured on-site and assembled on-site. This method leads to the installation of unhealthy pipe systems due to inappropriate working conditions of the field and the inability to bring the necessary equipment to the field. In addition, dirty pipe interiors due to dusty areas cause loss of time and extra costs during the flushing phase. Our engineering team prepares three-dimensional isometrics of the pipes using computers according to field measurements. Spools are prepared in our workshop according to these prepared isometric drawings. Hydraulic pipes, after welding and bending processes are completed, are cleaned with a puff, then flushed, and final cleaned. Once the cleaning is completed, the flange covers are closed and covered with stretch film. Spools are labeled for easy identification of pipes in the field.

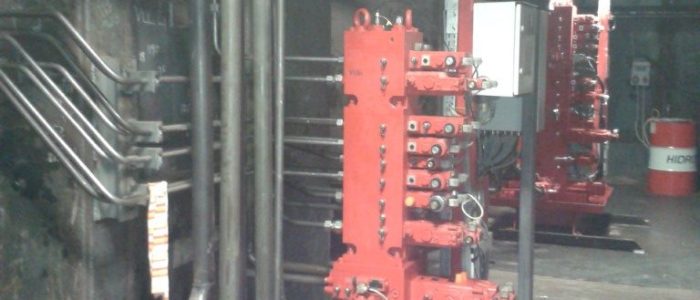

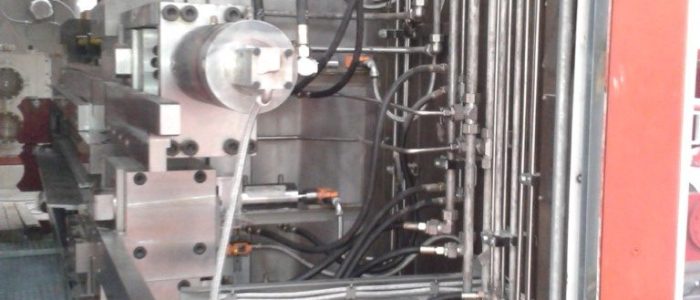

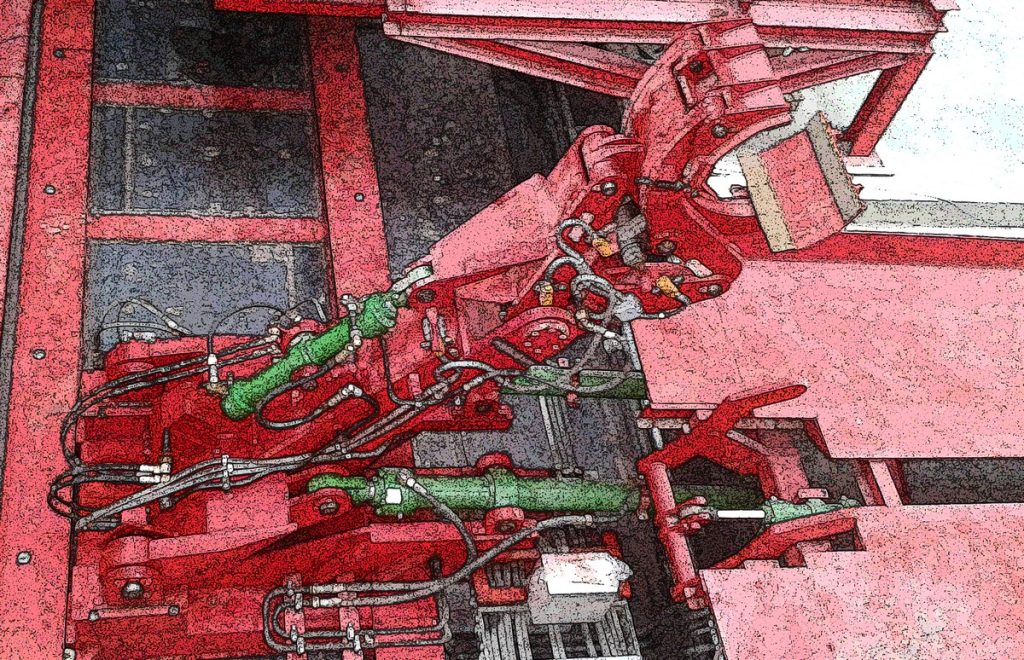

Gallery;