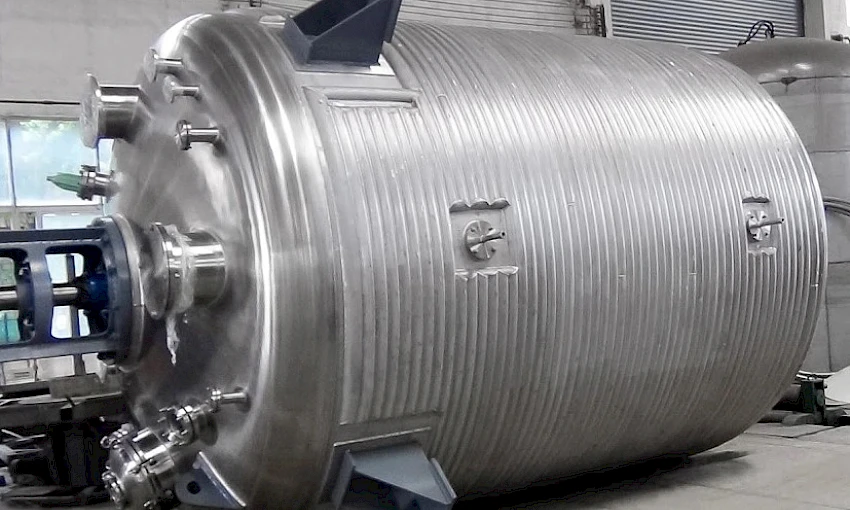

Stainless Reactor

Stainless Reactor

"Leading companies from many industries around the world rely on Aces brand Stainless Reactors in which chemical reactions take place. There are good reasons for this"

Stainless reactors; It provides the environment where substances come together and react chemically and brand new compounds are formed. Aces aims to fully reflect the power, impact and importance of Stainless Reactors in the industry.

Stainless Reactors are used for many processes such as chemical synthesis, crystallisation, catalytic reactions, polymerisation, fermentation, separation, reaction optimization. Stainless steel is a material that can prevent corrosion and erosion, so they offer a long-lasting and safe performance in chemical environments. Stainless steel reactors are used in industries such as pharmaceuticals, food, detergent, biodiesel, mineral oil, polyurethane, polyester, especially in chemistry. Reactors are the main equipment of industrial processes and provide high efficiency.

Stainless steel reactors can be coated with materials such as polyethylene, polypropylene or PTFE (Polytetrafluorethylene). These coatings prevent corrosion of chemical substances that come into contact with the inner surface of the reactor. In addition, stainless steel reactors can be equipped with temperature control systems or cooling systems, allowing reactions inside the reactor to be carried out at the desired temperature.

Stainless steel reactors are used in a wide range of chemical industry applications. Stainless steel reactors, which are used in the process of synthesising drugs in the pharmaceutical industry, are indispensable in the production or storage of chemicals in the chemical industry and in the food industry due to their hygienic, corrosion-resistant and bacteria-free structure.

Stainless steel reactors are an important option for the industry due to their robust structure, long-lasting performance and ability to come into contact with chemical substances. However, the use of stainless steel reactors requires a good understanding of the properties and reactions of the chemicals in the reactor and the use of appropriate control mechanisms. There are many reasons why stainless steel reactors are a preferred material for many chemical industry applications. Firstly, stainless steel is a corrosion resistant material. One of the most important advantages of stainless steel reactors is their corrosion resistance. Resistance to corrosive environments in stainless steels is quite high. Low alloy stainless steels are particularly resistant to atmospheric corrosion, while high alloy stainless steels have higher corrosion resistance. When used in chemical environments, an oxide layer is formed on the surface of the stainless steel to prevent corrosion. This oxide layer prevents the contact of chemical substances with the surface and prevents damage to the inner surface of the reactor.

Classification of stainless reactors according to the contact forms of the phases can be made as follows.

1. gas-liquid 2. liquid-liquid 3. gas-solid 4. liquid-solid 5. gas-liquid-solid

After determining the energy form (shape), the catalyst and the phases in contact, the next step is to decide whether to run the reaction in a batch or continuous manner.

Stainless reactors are divided into two types in terms of volume, shape and method of operation:

- Batch reactors

(A typical batch reactor consists of a tank with agitator and integrated heating/cooling system. Batch reactors are generally used for small-scale production operations and for testing new processes. They are smaller and more flexible than continuous reactors).

- Continuous reactors

(Continuous reactors are systems widely used in industrial chemistry and biotechnology. These reactors are designed to sustain a chemical or biological reaction uninterrupted by a continuous fluid feed).

Stainless steel reactors can serve many different industries. They are most commonly used in the following industries:

1.Chemical industry: Stainless steel reactors provide an ideal internal environment for chemical reactions and have a long service life because they are corrosion resistant.

2.Food industry: Stainless steel reactors can be used in food production to provide a hygienic and clean environment.

3.Pharmaceutical industry: Stainless steel reactors can be used in the production of pharmaceutical products and provide a hygienic environment.

4.Energy industry: Stainless steel reactors can be used in power generation plants.

5.Pharmaceutical industry: Stainless steel reactors are used for the pharmaceutical industry and provide a hygienic environment.

6.Special applications: Stainless steel reactors can also be used for special applications in other industries.

The advantages of stainless steel reactors include the following:

High efficiency: Reactors are designed to efficiently carry out chemical reactions during the process. This increases process efficiency.

Lower cost: Reactors enable to obtain a higher amount of product by using less amount of raw materials used during the process. This reduces production costs.

More control: Reactors provide control of parameters such as temperature, pressure, pH, ratio of reactants, mixing speed. This allows the process to be carried out more accurately, resulting in a higher quality product.

Scalability: Reactors can be scaled from small-scale laboratory experiments to large-scale industrial production.

Environmentally friendly: Reactors used in the pharmaceutical industry provide a more environmentally friendly production by minimising waste and pollutant emissions.

Innovative products: Reactors play an important role in synthesising new chemical compounds. In this way, more innovative products are produced in the chemical industry.

Safety: Reactors increase occupational safety by ensuring that chemical reactions are carried out in a controlled manner during the process.

Hygienic properties: Stainless steel reactors are preferred in sectors that require hygiene such as food and pharmaceutical production.

Another advantage of Aces brand stainless steel reactors is their mechanical strength and long service life: We use 100% certified raw materials in our production. We especially prefer raw materials that use cold forming method in the consolidation of stainless steel. With this method, the mechanical strength values of the material are increased. Due to their high temperature resistance, corrosion resistance and ability to operate under vacuum, our stainless steel reactors are an indispensable part of industrial facilities.

Stainless reactors can be defined as a process that enables the conversion of the desired product into the desired product with or without any reaction. Reactors are manufactured from very durable stainless materials and have a large internal volume. In reactors, processes such as mixing, heating, cooling, cooling, pressurisation can be performed and they can also operate under vacuum.

Stainless steel reactors are also heat resistant and can be used at high temperatures. This makes it possible to carry out chemical reactions inside the reactor at high temperatures or to control the internal temperature of the reactor. Stainless steel reactors are also easy to clean and sterilise. The environments in which chemicals are used are difficult to clean, but the surfaces of stainless steel reactors are easily cleaned and sterilised. Finally, stainless steel reactors can be used in a wide range of volumes. It offers a wide range between small volume laboratory reactors and large volume industrial reactors.

However, there are some points to be considered when using stainless steel reactors. Firstly, the surfaces of stainless steel reactors can be sensitive to mechanical abrasion or impact, so appropriate protection measures should be taken. Also, some chemical substances can cause corrosion on the surface of stainless steel reactors, so the properties and effects of chemical substances in the reactor should be carefully investigated. In particular, some chemicals such as acids, bases, halogen substances and organic solvents can cause corrosion on the surface of stainless steel reactors. Therefore, considering the properties and effects of the chemicals in the reactor, the appropriate stainless steel grade should be selected and necessary precautions should be taken. In addition, for the use of stainless steel reactors, the chemical reactions inside the reactor must be controlled and monitored. For example, the temperature, pressure and pH value inside the reactor must be controlled. For this purpose, control mechanisms such as temperature control systems, pressure control systems and ph control systems are added to the reactors. As a result, stainless steel reactors are a suitable option for industrial applications where chemical processes are carried out or chemical substances are stored. However, for the use of stainless steel reactors, factors such as the properties and effects of the chemical substances in the reactor, the structure and inner surface of the reactor, and the control of reactions in the reactor should be taken into account.

One thing to be considered in the design of stainless steel reactors is to know the viscosity values of the product to be mixed. (Viscosity; Viscosity, viscosity, fluidity or viscosity is a measure of the resistance of a fluid to wear under surface tension. It can also be defined as the fluid's internal resistance to flow. All real fluids except super fluids show resistance to surface tension).

Stainless Reactor Technical Specifications;

-Our reactors, which are designed and manufactured in accordance with customer requirements, are equipped with appropriate components such as both mechanical and soft seals.

-Our products are manufactured in accordance with ATEX / EXPROOF standards, thus providing a safe use.

-Our technological features such as PLC management panel, agitator speed control with inverter and loadcell precision weighing system ensure that our products perform at the highest level.

-We work with design and manufacturing principles in accordance with international standards such as PED, CE, AD2000, ASME. In this way, we offer high quality and long life guarantee to our customers.

-AISI 304, 304L, 316, 316L, 316Ti quality and certified stainless steel materials keep the quality of our products at the highest level.

-In our products, we use jacket or half pipe coils in the outer body and drawn pipe coils in the inner part. We also provide thermal insulation with insulation to increase the energy efficiency of our products. (The highest heat transfer coefficient in reactors is obtained with inner pipe coil and the lowest heat transfer coefficient is obtained with outer body jacket application).

-With our specially designed features such as agitator blades, wave breakers or foam breakers, we increase the operating performance of the reactors. (In a stirred tank reactor; reactants, heat exchangers, agitators and headers, antifoam and wave breakers are required to prevent vortex formation and increase turbulence and increase mixing).

In addition, we carry out meticulous work on documentation and certification. Thus, our customers can easily familiarise themselves with the detailed technical specifications and operating instructions of our products.

If you are looking for a company specialised in the production of high quality reactors, you are in the right place. Our company offers our customers customised reactors using the latest technologies.

The reactors we offer to our customers are manufactured using high quality materials and state-of-the-art production equipment. Our products have been tested and approved by industry leaders, thus providing our customers with a reliable solution.

We also strive to provide our customers with the highest level of customer service. We provide you with a customised solution to meet your needs and offer maintenance and repair services to extend the life of our products.

If you are looking for a high quality, customised and reliable reactor, you can be sure that our company is the best option for you. Feel free to contact us and have the best solution to meet your needs.

Keywords;

Reactor

Reaction Vessel

Stainless Reactor

Chemical Reactor

304 steel reactor

316 steel reactor

Titanium Reactor

Stainless Reactor Manufacturing

Reactor Prices

Pilot Reactor

Glue Reactor

Copyright by @AcesTeknik. All Rights Reserved