Heat Exchangers

HEAT EXCHANGERS

Temperature and energy management play an important role in every aspect of our lives. Our heat exchanger manufacturing company offers the most innovative and high quality solutions in this field.

Specially designed heat exchangers for our customers provide excellent performance even in the most demanding applications thanks to their high efficiency and durability. Our products are designed to be used in a wide range of applications and can be customized for any application.

By using environmentally friendly and energy efficient technologies, our heat exchangers minimize our customers' energy consumption while reducing their impact on the environment. Furthermore, the low maintenance requirements of our products help our customers to reduce their operating costs.

You can benefit from the advantages of energy saving and environmentally friendly technologies by working with our company, which offers the most innovative and high quality solutions for your heat exchanger needs. You can get more information and contact us for customized solutions by visiting our contact information.

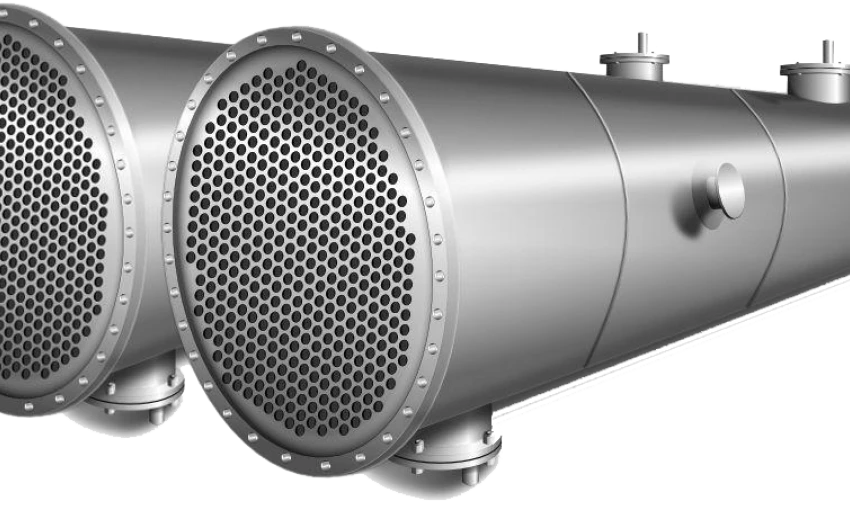

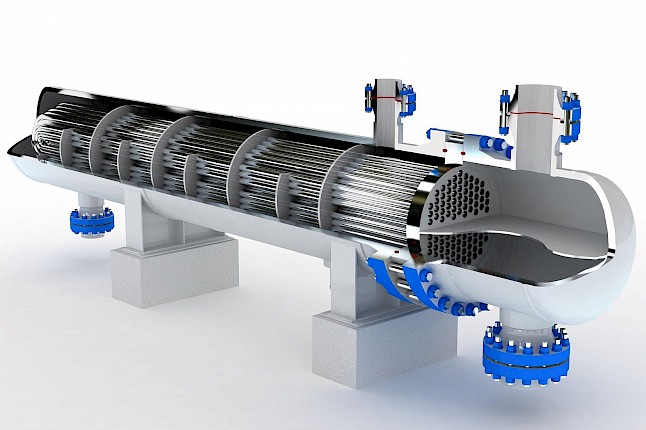

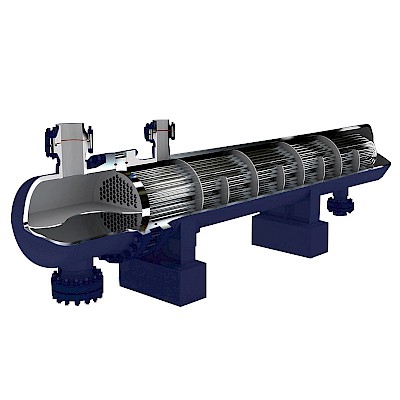

TUBE HEAT EXCHANGERS

A tube heat exchanger is a type of heat exchanger used for heat transfer. A tube heat exchanger is a structure in which small tubes, called pipes, are neatly arranged and connected together. It is used for two different fluids (usually liquid or gas) to transfer heat.

Tube heat exchangers are widely used in many industrial applications. For example, they can be used in many sectors such as heating, ventilation and air conditioning (HVAC) systems, power generation, chemical processes, food and beverage industry.

The advantages of tube heat exchangers include factors such as high heat transfer efficiency, low cost and long life. Furthermore, tube heat exchangers are available in various sizes and configurations, making them suitable for a variety of applications.

A heat exchanger is a device designed to transfer heat in a controlled manner between two or more fluids or between a solid surface and a fluid. Heat exchangers are used in a wide range of industrial, commercial and residential applications to transfer thermal energy from one medium to another. The basic principle of a heat exchanger is to use a fluid, typically water or air, to transfer heat from one medium to another. In a typical heat exchanger, the two fluids flow in opposite directions, with the hot fluid entering the exchanger at one end and the cold fluid entering at the other end. As the fluids flow through the heat exchanger, heat is transferred from the hot fluid to the cold fluid, resulting in a decrease in the temperature of the hot fluid and an increase in the temperature of the cold fluid. There are many different types of heat exchangers, including shell and tube, plate and frame and spiral heat exchangers. Each type has its own unique design and operating characteristics and is suitable for different applications depending on factors such as the required heat transfer rate, fluid pressure and temperature ranges and corrosion resistance. Heat exchangers are used in a wide range of applications, including heating and cooling systems, power generation, chemical processing, food and beverage processing and HVAC (heating, ventilation and air conditioning) systems. They play an important role in improving energy efficiency and reducing energy consumption, as well as reducing greenhouse gas emissions by enabling waste heat to be recovered and reused.

One of the key advantages of using a heat exchanger is that it allows efficient heat transfer without the need for direct contact between the two fluids. This can help prevent fouling and maintain the integrity of the fluids being transferred. In addition, heat exchangers can be designed to operate at high pressures and temperatures, making them suitable for use in a wide range of industrial and commercial applications. Another advantage of heat exchangers is that they can be customized to meet specific requirements and performance criteria. For example, heat exchangers can be designed with different types of tubes or plates, varying flow rates and different heat transfer surfaces to optimize their performance in different applications. They can also be made of various materials to ensure compatibility with different fluids and resistance to corrosion, erosion and other forms of wear and tear. In general, the benefits of using a heat exchanger often outweigh the disadvantages, especially in applications where efficient heat transfer is critical to maintain process efficiency and reduce energy consumption. As such, heat exchangers are an essential component of many industrial, commercial and residential systems, and their use is likely to continue to increase as energy efficiency becomes an increasingly important consideration in the design and operation of buildings and processes.

Heat exchangers are typically a part of manufacturing processes that involve the design, engineering, fabrication and assembly of the various components of the heat exchanger.

Anahtar kelimeler;

#Exchanger

#Tube Exchanger

#heat exchanger

#Condenser

#Body Tube Exchanger

#Exchanger Manufacturing

#Exchanger Prices

Copyright by @AcesTeknik. All Rights Reserved