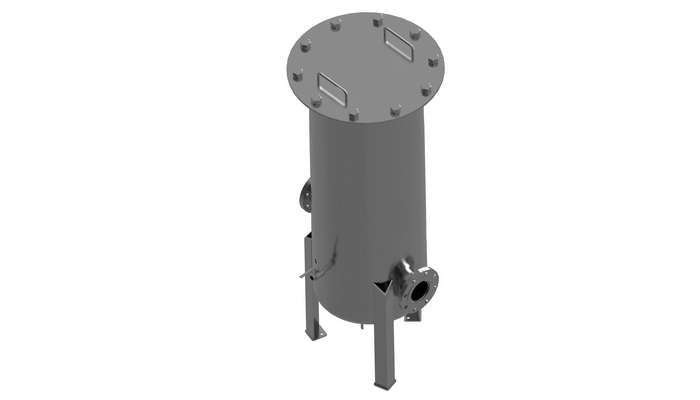

Filter Housing

The filter housing essential components in filtration systems

01.

Filter housings are essential components in filtration systems

Designed to encapsulate and protect filter elements such as cartridges or bags. Typically constructed from durable materials like stainless steel, plastic, or aluminum, these housings are engineered to withstand high pressure, temperature fluctuations, and corrosive environments.

02.

Key features and benefits filter housing

Durability and Longevity: Quality filter housings are built to endure harsh industrial conditions, offering resistance to chemicals, extreme temperatures, and physical wear. This durability minimizes the need for frequent replacements, reducing maintenance costs and downtime.

Versatility: Available in various sizes and configurations (single, multi-round, or high-flow), These products can accommodate different types of filters for specific applications. Multi-stage housings, for example, are ideal for processes requiring various filtration levels within a single system.

03.

Efficiency in Filtration: Properly designed filter housings optimize flow rates and filtration efficiency, ensuring that the system performs consistently without excessive energy consumption or clogging issues. Effective sealing mechanisms, like O-rings and clamps, prevent leaks and maintain system pressure.

Ease of Maintenance: Designed for easy access, allowing quick filter changes without significant disruption to the overall system. Some housings also feature integrated pressure gauges or drain ports for better maintenance and monitoring.

Customization: For specialized applications, filter housings can be customized in terms of size, configuration, and material. This flexibility allows industries like pharmaceuticals, food and beverage, and chemicals to meet specific regulatory or operational needs.

04

Applications

Pharmaceuticals: Used in processes that demand sterile environments, ensuring purity and safety.

Oil and Gas: Filtering impurities from fuels, protecting pipelines, and enhancing downstream equipment longevity.

Food and Beverage: Removing particulates and contaminants, safeguarding product quality, and adhering to food safety standards.

Water Treatment: Filtering sediments, particles, and contaminants to provide clean and safe water supplies.

You can click the link to get more information about filters.