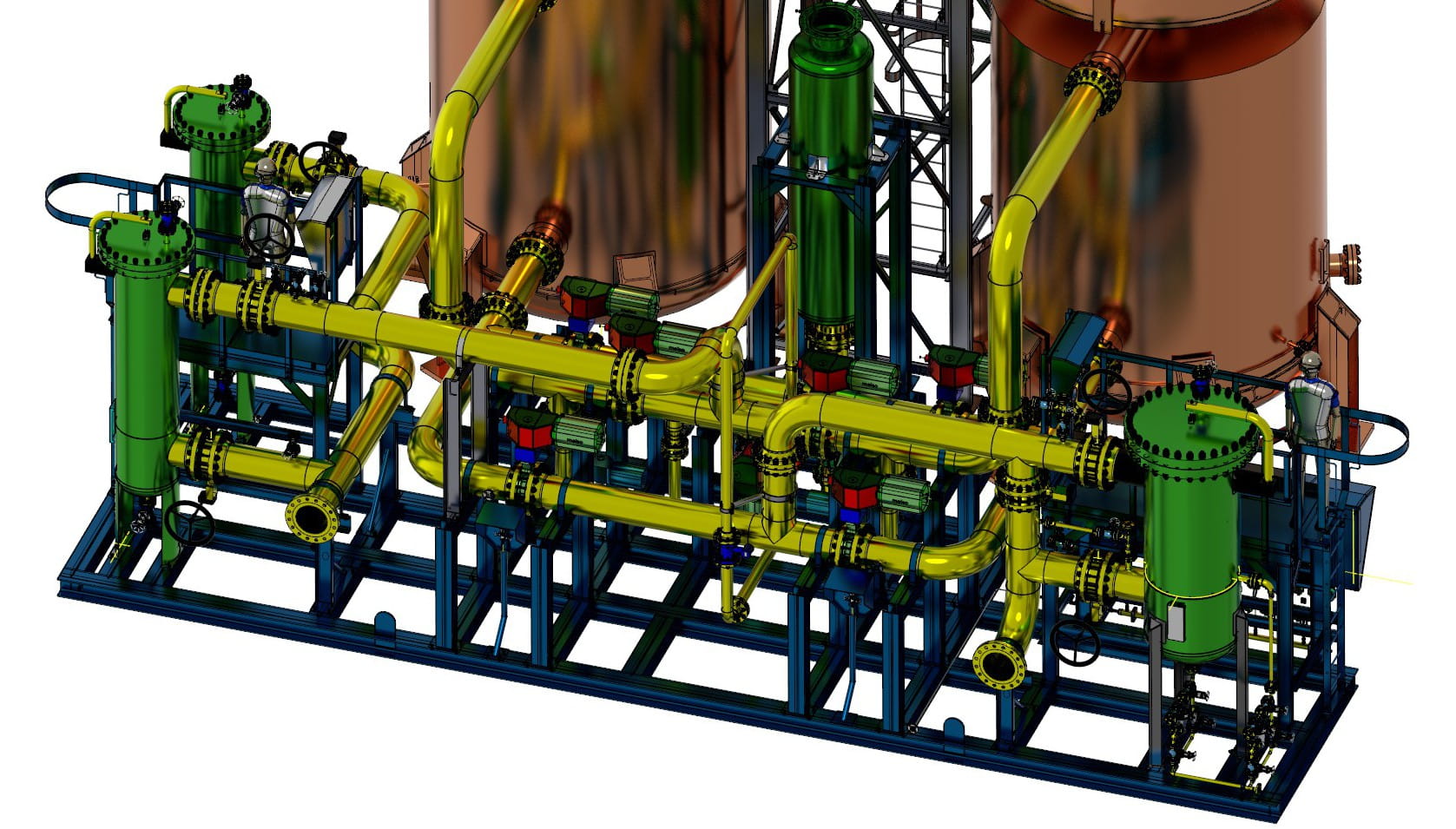

A modular process skid is a process system housed in a frame that allows easy transportation of the process system (skid assembly). Individual skids can include complete process systems, and multiple process skids can be combined to create larger process systems or entire portable plants. Sometimes these are called “systems in a box”. An example of a multi-skid process system may include a raw material skid, an utilities skid, and a processing unit working together.

Portable design – because they are self-contained units built within frames, skid systems are easier to transport than traditional process systems

Small footprint – process skid frames allow equipment to be layered. Pipes, tanks, and necessary process equipment can be fitted into a smaller space with the skid design.

Consolidated process connections – process connections are concentrated in a single point on the skid, simplifying plant connections. In traditional process systems, connections are spread throughout the plant.

Controlled assembly – skids are often built off-site in controlled conditions. Existing operations are not affected by skid production.

FAT testing before installation – Factory acceptance testing (FAT) can be completed before modular process skids are shipped to the field. This reduces on-site startup time.

Accessible layout design – skids are designed for accessibility; usually include a center aisle and the main pieces of equipment are placed on the edge of the frame.

While modular skid systems used to be used only in the maritime sector, they have started to be used in every sector in recent years.